Guangdong Ecocampor Vehicle Co.,Ltd

#1 Quality Certified Camper Manufacturer, We Create Custom Solutions to Fit Your Needs

At Kinlife, our mission is to enhance camping experiences by making them easier and more enjoyable.

Having already served countless adventurers, we’re now focused on refining campers to pack more amenities into compact designs. Feedback from users and dealers remains vital in driving these innovations forward.

Extensive Range of Camper For You

At Kinlife, we empower brands through our versatile camper solutions. With a 60,000-sqm production facility and custom design drawings delivered within 1 hour, we provide fast, reliable support to elevate your business operations.

Camper Manufacturer

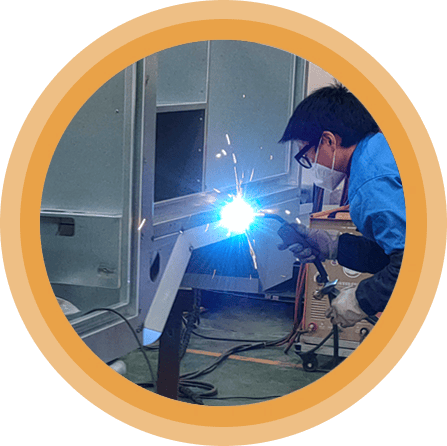

Kinlife Factory Tours

At Kinlife, we invite you to witness our camper creation process firsthand—from design customization to rigorous quality control and global shipping. Tour our facilities to experience precision manufacturing in action. Contact us today for same/next-day responses to schedule your visit.

What did our happy clients say?

We worked with Kinlife for more than 3 years, product quality well met with the Australian market.

Question And Answer

How many people are usually in your camping group?

What size of vehicle are you looking for?

How many people are usually in your camping group?

Do you need to use the pop-up roof feature to expand the interior space?

How many people are usually in your camping group?

For your sleeping environment, do you prefer a tent or inside the vehicle?

Frequently Asked Questions

Here are 6 FAQs to help guide you through the process: