Your Reliable Truck Camper Manufacturer

OEM manufacturing with full customization options

As an experienced truck camper manufacturer, we bring together engineering, design, and skilled production to deliver durable, well-crafted campers.

Choose from our best-selling truck camper models or request a custom build tailored to your market.

s a dedicated truck camper manufacturer, our team of engineers, designers, consultants, and skilled technicians work together to deliver high-quality, durable units — from slide-in and pop-up truck campers to rugged off-road models. We also offer full OEM customization, advanced testing, and reliable manufacturing to bring your camper ideas to life.

Slide In Camper

Slide On Camper

Hey, explore our Truck Camper now—email us for a quote!

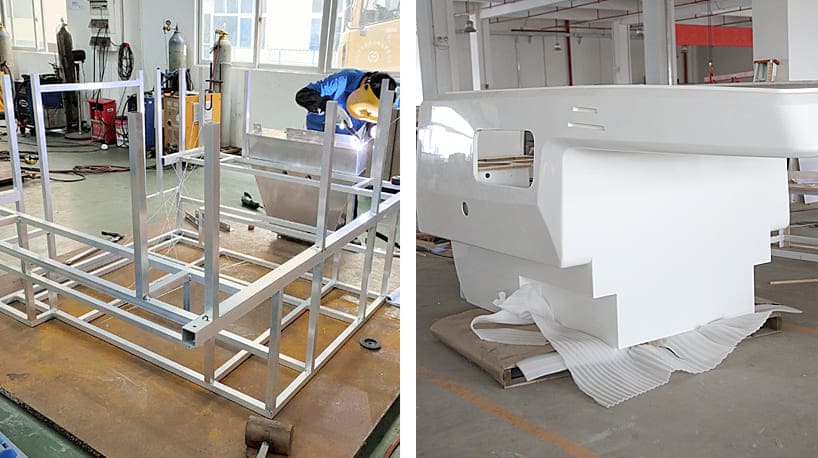

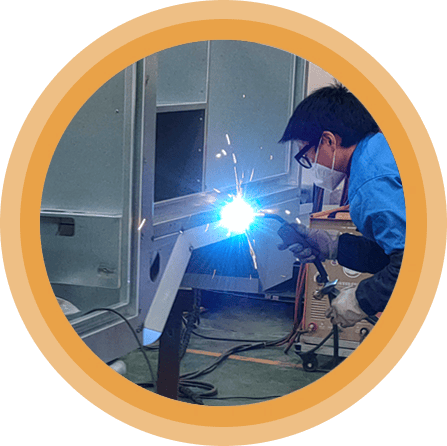

How We Build Your Truck Camper — Real Production Workflow

#1 Structural Floor & Sub-frame Preparation

We begin by fabricating the camper floor using composite panels or aluminum-reinforced structures. A reinforced sub-frame is assembled with mounting points to match common pickup beds. This base supports the entire unit’s structural integrity and provides attachment zones for cabinetry and outer walls.

#2 Shell & Wall Framework Integration

Aluminum or steel framing is constructed and precisely aligned on top of the floor. Structural ribs are added to reinforce the side walls, cab-over sections, and rear wall. Corners are secured with brackets or bonded joints, forming the full shell’s framework.

#3 Panel & Composite Skin Installation

We apply insulated sandwich panels made from FRP, fiberglass, or aluminum-clad foam-core to the frame. These provide strength, weather resistance, and thermal insulation. After wall and roof panels are installed, all seams and openings are sealed with industrial-grade waterproofing systems.

#4 Interior, Cabinets & System Installation

Once the shell is complete, we install interior modules including sleeping platforms, dinettes, kitchenettes, and optional wet baths. Simultaneously, electrical wiring, water lines, and ventilation systems are routed and secured inside the walls and ceiling. Every layout is optimized for space and function.

#5 Final Assembly, Testing & QA

Final systems such as lighting, appliances, windows, doors, and exterior hatches are installed. The camper is then tested for leaks, wiring continuity, and overall structural soundness. After inspection, branding, decals, and optional customer add-ons are applied before final packaging and shipment.

You can totally trust us with all certifications shown below

Raw Material Sources

Your products are produced by the raw material from our proud partners below:

Our Truck Camper Materials

If you are a teardrop trailer manufacturer, we are not a competitor but a cooperative partner. We provide a range of high-quality materials and components to enhance your trailers’ durability and reduce production costs.

What did our happy Partners say?

We worked with ecocampor for more than 3 years, product quality well met with the Australian market.

Truck Camper FAQs

Business Opportunity for Wholesalers

We are seeking wholesalers and dealers who are interested in distributing this camper.

Fill out the form to get a quote for these off-road camper trailers.

We will give you the best quote.